Environment and Social Management System: Enhancing Supply Chain Sustainability

Introduction

In today’s globalized world, supply chains play a crucial role in the success and reputation of businesses. With increasing awareness about environmental and social responsibility, companies are realizing the importance of integrating an effective Environment and Social Management System (ESMS) into their supply chain management practices. ESMS helps organizations identify, manage, and mitigate environmental and social risks, ensuring sustainable operations and positive impacts on communities and stakeholders.

Importance of ESMS in Supply Chain Management

Integrating an Environment and Social Management System (ESMS) into supply chain management is of utmost importance for businesses in today’s socially and environmentally conscious landscape. ESMS ensures that companies consider and address the environmental and social impacts of their supply chain activities, leading to several significant benefits.

Firstly, ESMS helps companies identify and mitigate environmental and social risks throughout their supply chains. By conducting thorough assessments and evaluations, organizations can proactively identify potential issues and implement measures to minimize their negative impacts. This proactive approach not only safeguards the environment but also protects the well-being of communities and stakeholders involved in the supply chain.

Secondly, implementing ESMS promotes sustainability and responsible practices. By setting clear goals and targets for sustainable operations, companies can optimize resource utilization, reduce waste generation, and minimize pollution. This not only reduces the ecological footprint but also leads to cost savings and operational efficiencies in the long run.

Thirdly, ESMS enhances brand reputation and stakeholder trust. In an era where consumers and investors increasingly prioritize ethical and sustainable business practices, companies that demonstrate their commitment to environmental and social responsibility gain a competitive edge. By integrating ESMS into supply chain management, companies can strengthen stakeholder relationships, attract socially conscious customers, and access new markets that value sustainability.

Furthermore, ESMS fosters transparency and accountability. Through regular reporting and monitoring, companies can track their environmental and social performance, identify areas for improvement, and demonstrate compliance with relevant regulations and industry standards. This transparency builds trust with stakeholders and allows for effective communication of sustainability efforts.

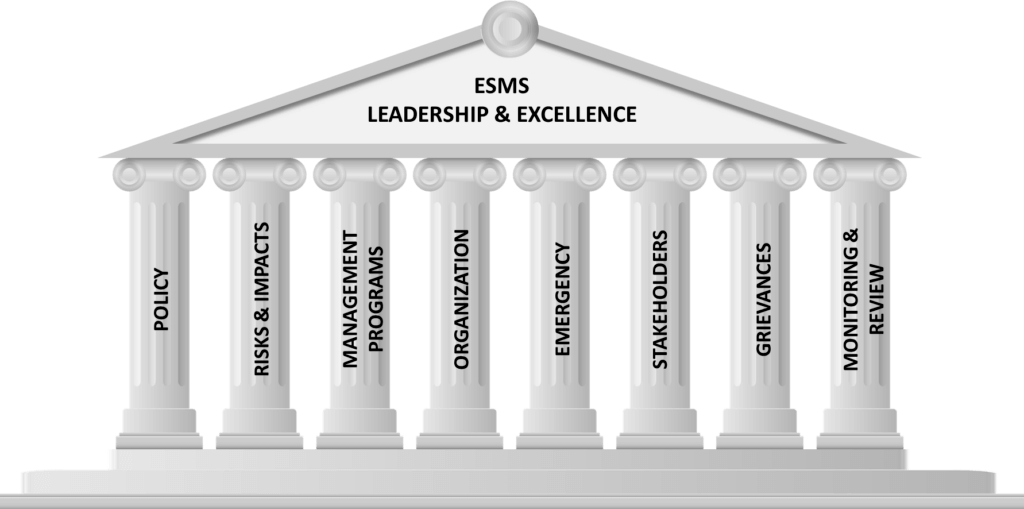

Pillars of ESMS

1. Policy

A strong foundation for any ESMS lies in the development and implementation of a comprehensive policy. This policy outlines the organization’s commitment to environmental and social responsibility, setting the tone for sustainable practices throughout the supply chain. It should align with international standards and best practices, and clearly define the company’s goals, objectives, and strategies for managing environmental and social impacts.

2. Identification of Risks & Impacts

Understanding the potential risks and impacts on the environment and society is crucial for effective ESMS implementation. This involves conducting thorough assessments and evaluations to identify potential environmental and social risks associated with the supply chain activities. By analyzing the entire lifecycle of products and services, companies can identify areas where they can minimize their ecological footprint and enhance social well-being.

3. Management Program

A robust management program forms the core of ESMS implementation. It includes the development of strategies, procedures, and guidelines for addressing identified risks and impacts. This program establishes a structured approach to resource management, waste reduction, pollution prevention, and social engagement. By integrating sustainable practices into daily operations, organizations can optimize resource utilization, minimize environmental harm, and foster positive social outcomes.

4. Organization

Successful implementation of ESMS requires a dedicated team and well-defined roles and responsibilities. Organizations need to designate individuals responsible for overseeing and managing environmental and social aspects within the supply chain. This ensures accountability and facilitates effective coordination across different departments and stakeholders. Regular training and capacity-building initiatives should also be provided to empower employees and foster a culture of sustainability.

5. Emergency Preparedness

Preparedness for environmental emergencies is a critical aspect of ESMS. Organizations must develop contingency plans and response mechanisms to handle unforeseen events such as natural disasters or industrial accidents. By having robust emergency preparedness protocols in place, companies can minimize the negative impacts on the environment and local communities, while ensuring the safety of their workforce.

6. Stakeholder Engagement

Engaging with stakeholders, including local communities, NGOs, suppliers, and customers, is vital for the success of ESMS. Companies should establish regular communication channels and consultation processes to gather feedback, address concerns, and incorporate diverse perspectives. By actively involving stakeholders in decision-making processes, organizations can build trust, enhance transparency, and create shared value.

7. Grievance Handling

ESMS implementation should include a mechanism for addressing grievances raised by stakeholders. Companies should establish a clear and transparent process for receiving, investigating, and resolving complaints related to environmental and social issues. Promptly addressing grievances not only demonstrates a commitment to accountability but also provides an opportunity for continuous improvement and strengthening of relationships with stakeholders.

8. Reporting and Monitoring & Review

To track progress and ensure the effectiveness of ESMS, regular monitoring, reporting, and review mechanisms should be established. Companies should define key performance indicators (KPIs) and implement systems to collect relevant data. Periodic assessments and audits help identify areas for improvement, measure the achievement of goals, and facilitate informed decision-making. Transparent reporting on environmental and social performance promotes accountability and facilitates benchmarking against industry standards.

The Role of Leadership in ESMS Implementation

Successful implementation of ESMS requires strong leadership commitment. Top management must champion sustainability as a core value and integrate it into the organization’s culture.

Top management should actively participate in setting the strategic direction for ESMS and allocate adequate resources to support its implementation. They should lead by example and promote a culture of sustainability throughout the organization.

Leadership plays a crucial role in driving change and inspiring employees to embrace sustainable practices. By effectively communicating the importance of ESMS and its benefits, leaders can foster a sense of ownership and engagement among employees. They should encourage innovation and provide necessary training and guidance to ensure that everyone understands their roles and responsibilities in achieving sustainability goals.

Furthermore, leaders should regularly review and evaluate the progress of ESMS implementation. They should monitor key performance indicators, assess the effectiveness of initiatives, and make necessary adjustments to enhance performance. By demonstrating their commitment to continuous improvement, leaders can motivate employees and create a culture of accountability and excellence.

Partnership Between Companies in the Supply Chain

Collaboration and partnership between companies within the supply chain are vital for effective Environment and Social Management System implementation. When companies work together, they can share knowledge, resources, and best practices, leading to collective improvement in environmental and social performance.

The partnership enables companies to align their sustainability goals and coordinate efforts to address common challenges. By collaborating on initiatives such as responsible sourcing, waste management, and community engagement, companies can leverage their collective influence to drive positive change.

Sharing best practices and lessons learned fosters innovation and encourages the adoption of more sustainable approaches. Through collaboration, companies can identify and implement cutting-edge technologies, processes, and policies that have a positive impact on the environment and society.

Moreover, partnership enhances trust and transparency within the supply chain. By openly sharing information on environmental and social performance, companies can build strong relationships based on mutual respect and shared values. This transparency extends to stakeholders, including customers, investors, and communities, who increasingly expect companies to demonstrate responsible supply chain practices.

Conclusion

In an era where sustainability and social responsibility are paramount, integrating an effective Environment and Social Management System (ESMS) is crucial for companies seeking to enhance their supply chain management practices. By embracing the pillars of ESMS – including policy development, risk identification, management programs, stakeholder engagement, and reporting – companies can minimize environmental and social risks, drive positive change, and create long-term value.

Leadership commitment, resource allocation, and continuous monitoring are vital for successful ESMS implementation. Additionally, collaboration and partnership between companies in the supply chain foster knowledge sharing, innovation, and collective improvement in sustainability practices.

Embracing ESMS not only aligns businesses with global standards and best practices but also enhances their reputation, fosters stakeholder trust, and contributes to a more sustainable future.