section-ed7d92c

Operational Audits: Tool for Continuous Improvement

Managing operations of any kind, be it manufacturing, logistics or services, is getting tougher by the day. Considering unpredictable scenarios, volatile environment and numerous micro and macro factors impacting the operations, it is unfair to assume that managers & people will have a razor-sharp focus on operational efficiency and effectiveness. When the pressure mounts, people tend to take short-cuts and make their own informal procedures which could be detrimental in the long run.

It reminds me of a case when we had a temporary problem with a regular transporter and had to allow non-contracted transporters to ensure timely delivery to the customers. It meant higher cost and a risk of working with unknown carriers. However, even after the regular transporter resumed normal services, the delivery staff continued to use non-contracted transporters on some pretext or the other. It was discovered when one of the vehicles of one such transporter went missing along with the products.

Need for the Operational Audits

The purpose of an operational audit is to improve the efficiency of day-to-day operations as well as identify risks due to non-compliance to the set procedures & policies. The audits provide a feedback loop to the operational managers based on the assessment of the effectiveness of the processes. These are not same as the internal audits, conducted by the audit department once or twice every year. The operational audits must be carried out as frequently as deemed important. For example, for a laboratory in the pharma manufacturing unit the, 5S audits may be required at a weekly frequency whereas the Contamination audits may be done once every month. For a warehouse operation, the cost efficiency audits may be done once a quarter while the stock audits may be required every month.

Operational Audits are different from Internal Audits

Operational audit programs are much more in-depth than normal internal audits. They do not look at how things are, they also look at how things could be. In one of the examples of the warehouse audit, the auditor discovered that the pickers are travelling to the same area of warehouse multiple times during the observation period. On further investigation, it was found that the orders are being picked individually for each customer order. However, the back & forth movement of the pickers for each order was not only inflating the need for more manpower but also slowing down the operation. The auditor recommended the change in the picking method to batch picking which led significant reduction in picking time & cost. From an internal audit perspective, there was no gap in the process but from the operational audit perspective, there was a significant opportunity for improvement. That is where the operational audits distinguish from the internal audits.

Another important aspect of the operational audit is that the auditors can be from the same team or the operational excellence experts from within the organization.

We already have Metrics in place to monitor and improve performance, then why Operational Audits?

Metrics and performance indicators are the outcomes and by the time the problems translate into visible outcomes, it is often too late. The operational audits are proactive in nature and used to isolate the problems right at its inception. Much before it is big enough to show up in the performance metrics.

A simple example from daily life is effect of your eating habits on the weight. Even though you measure weight on daily basis it may take many days or months before it starts reflecting on the weighing scale. On the other hand, if you audit what you eat and take corrective actions on daily basis, you can be assured about the positive impact on the body weight.

Structuring the Operational Audit Program

A meaningful operational audit program needs to be well-structured and planned to deliver effective results. The steps involved are:

- Prepare an Audit Plan:

- Depending on the nature of operations, one needs to start with defining the key outcomes of the processes that are part of the operations. As mentioned in the examples above, for a lab operation, it is the maintain the hygiene and prevention of contamination that is critical, whereas for customer service operations, it is the accuracy and timeliness, apart from the cost that is important.

- Decide whether all the outcomes can be clubbed in a single audit or divided into 2-3 different types of audits. The idea is not to make audit program too complex yet manageable. For example, for a warehouse audit the safety and compliance could be clubbed into one audit whereas the cost, service, and quality into another. Considering the higher risk associated with safety and compliance, it can be conducted more frequently as compared to the other audit.

- A sample audit plan may look like:

Operation

Audit Areas

Need for Audit

Frequency

Audit Responsibility

WarehouseSafetyCompliance

To fulfil the corporate policy of zero tolerance to safety and complianceMonthlyWarehouse ManagerWarehouseCostQuality

To achieve the set cost & quality objectivesQuarterlyRegional Logistics ManagerWarehouseHygiene / 5STo prevent the contamination of productWeeklyWarehouse SupervisorCustomer ServiceAccuracyQuality

Cost

To reduce the number of errors and increase the customer satisfaction scoreQuarterlyOperational Excellence Manager - Define Audit Criteria or Checklist:

For each audit type, determine the reference or standard to be used for the assessment e.g. ISO standard or Risk & Control Matrix. If you don’t have one, it can be developed as below:- Map the key activities for each process involved. For example, in warehouse operation the key safety areas include the movement of vehicles in the yard, loading & unloading operations, use of material handling equipment and storage of products.

- Now, assess the risk involved in each area and the controls that need to be in place to mitigate the risk. For example, the risk involved in the movement of vehicles in the yard is the accidents due to reckless or high-speed driving. The controls that need to be in place to mitigate the risk are putting a speed limit signboard, putting direction and markings for vehicular movement, installing convex mirrors at the sharp corners etc.

- Include all the important control points as the audit checklist. For each checkpoint, add the related best practice document or pictures that act as a guidance for the auditor.

Activity

Risk Involved

Risk Level

Control Measure

Guideline Document

Moving Vehicles in the YardAccidentsHighPut Speed Signages

Mark Directions for Vehicle MovementSignage - Size and Placement Guideline - Implement the Audit Program:

- The implementation requires communication with all the stakeholders and getting their buy-in. The stakeholders’ alignment becomes easier if the audit objectives are aligned to the business or functional objectives, as shown in the step 1.

- It must be communicated that the purpose of the audits is to drive continuous improvement and not to find faults with the auditee

- Select a suitable tool e.g. SIMSA, to minimize the manual efforts in managing the audit program

- Train the personnel responsible for conducting the audit on the process as well as using the tool

- Make a calendar of audits for each site, in agreement with the auditors and the auditees

Audit Title

Site

Dates

Auditor

Warehouse Safety & Compliance AuditSite ABCFrom dd/mm/yyyy to dd/mm/yyyyJohn SmithSite XYZFrom dd/mm/yyyy to dd/mm/yyyyJane Doe - Monitor the Audit Program:

Any program not subjected to periodic monitoring and review is likely to fail and the audit program is no exception to it. The purpose of the audit program review is to ensure:- Whether the audits are happening as per the calendar?

- Whether the reports are shared in a timely manner with all the stakeholders?

- Whether there are corrective actions in place for all the observed gaps?

- Whether the corrective actions are being closed in a timebound manner?

Monitoring an audit program can become extremely cumbersome without a dedicated tool like, SIMSA, which can not only pull all the information on click of a button but also send automated reminders to people, should there be any backlogs. The visibility of the status of the audit programs instils the seriousness and accountability in the organization

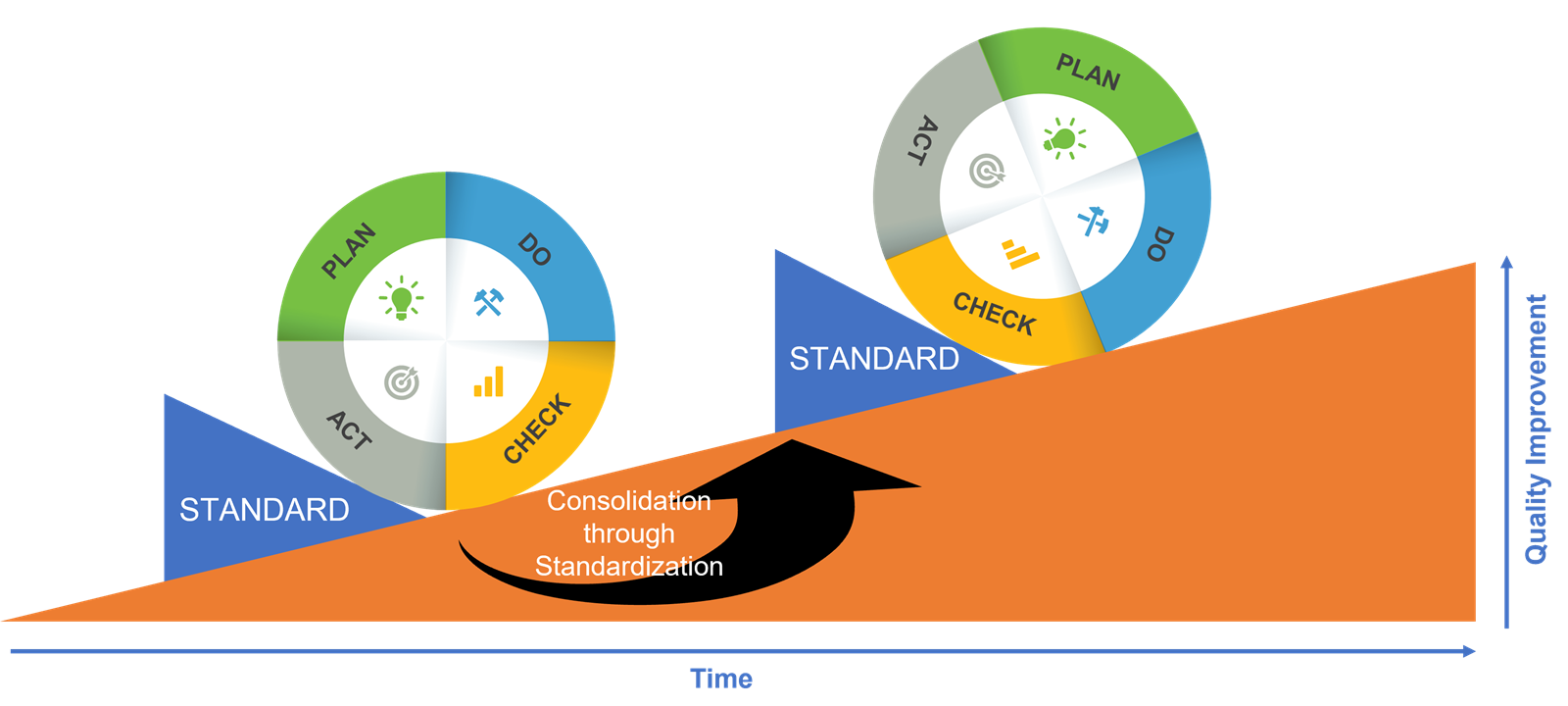

- Improving and refreshing the Audit Program:

In a dynamic environment, it would be naïve to assume that the risks, controls and audit criteria once decided can be used for ever. As the business priorities change or there is a change in the risk profile or the nature of controls, the audit program must be altered to accommodate these changes. Also, if certain deficiencies were found in the previous audit program, the same should be rectified. This approach aligns with the PDCA (Plan-Do-Check-Act) framework of operational excellence.

Source: How to Conduct a Quality Internal Audit, Seetharam Kandarpa

Conclusion:

It is obvious that operational audit is one of the important levers of continuous improvement. Unlike internal audits, the operational audits are proactive in nature because the focus is not what is not right but what could be done better. However, it has been seen that in most organizations the operational audits are missing or done in an adhoc manner. Therefore, it does not translate into any visible improvements. A well structured operational audit program supported by technology like SIMSA, can be an important tool in the hands of operational managers to drive the operational excellence.