Unlocking Efficiency: The Power of Operational Audits

In the fast-paced world of business, where every penny counts, efficiency is the key to success. Companies are constantly striving to maximize productivity, minimize costs, and stay ahead of the competition. In the relentless pursuit of efficiency, organizations often overlook a potent weapon in their arsenal: the operational audit. It’s time to challenge the prevailing mindset and explore how operational audits can not only identify weaknesses but also transform organizations into lean, mean, profit-generating machines. In this article, we’ll explore the concept of operational audits, their significance, and how they can be leveraged to unlock efficiency within an organization.

What is an Operational Audit?

An operational audit is a comprehensive examination of an organization’s internal processes, systems, and procedures. Its primary objective is to evaluate the efficiency and effectiveness of these processes. Unlike financial audits, which focus on monetary transactions, operational audits delve deep into the operational aspects of a business.

Operational Audits: More Than Just a Cost-Cutting Tool

The common perception of operational audits is that they are primarily about cost reduction. While this is undeniably a significant aspect, it’s crucial to recognize that operational audits offer much more. Let’s break down some examples to challenge the conventional wisdom:

Example 1: The Customer Service Conundrum

In many organizations, customer service is seen as an unavoidable cost. It’s often seen as a necessary expense rather than a potential source of revenue. Operational audits challenge this mindset. By examining customer service processes, an audit might uncover opportunities to turn customer interactions into revenue-generating moments. This could involve cross-selling, upselling, or improving the resolution time, ultimately enhancing customer loyalty and the bottom line.

Example 2: The “We’ve Always Done It This Way” Fallacy

One of the most damaging mindsets in any organization is the belief that longstanding processes are inherently efficient. Operational audits are a wake-up call to this fallacy. Take, for instance, a manufacturing plant with a production process that hasn’t changed in years. The audit may reveal that advancements in technology or changes in the market have rendered this process obsolete. By challenging the status quo, the audit can lead to transformative changes, like automation or process reengineering, that result in substantial efficiency gains.

Example 3: Resource Allocation Realignment

Many organizations tend to allocate resources based on tradition or political considerations rather than where they’re most needed. Operational audits have the power to challenge this resource allocation inertia. Let’s consider a department within a company that receives a substantial budget but contributes little to the organization’s overall goals. An audit might recommend a reallocation of resources to departments with more significant growth potential, challenging the established hierarchy and potentially fueling innovation.

Operational Audit Software | SIMSA: The Catalyst for Change

Operational audits aren’t passive exercises in data collection; they’re catalysts for transformative change. They challenge entrenched norms and reveal opportunities hidden beneath the surface. Here’s where the strength of operational audits lies:

Uncovering the Unseen: Operational audits delve deep into processes and systems, unearthing inefficiencies that might have remained hidden for years. They force organizations to confront the reality of their operations. Operational Audits not only point the leakages but also help identify the root causes of leakage. In short operational audits proactively identify the gaps in processes, practices before it creates a big impact. For example, an FMCG company could plug the wastages in sampling activity through audit of distributors’ operations.

Fact-Based Decision Making: Audits rely on hard data, not assumptions. They challenge gut feelings and opinions with concrete evidence, making it difficult to dismiss necessary changes. For example, a CFA operator handling empty bottles of beverages could identify reasons for excessive breakages by using the operational audit.

Accountability and Ownership: Audits assign responsibility for identified issues. They challenge individuals and teams to take ownership of problems and drive solutions. In the example of the FMCG company that identified the root cause of wastage in sampling, assigned the responsibility to the regional controller to review and update the sampling process to plug the leakage.

Continuous Improvement: Operational audits promote a culture of continuous improvement. They challenge organizations to evolve and adapt in a rapidly changing business environment. In a dynamic business environment, the processes have to keep a pace with the changing situations. Operational audits are a useful tool to know which processes need to be reviewed and updated.

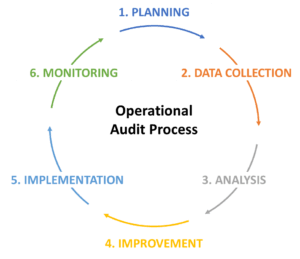

The Operational Audit Process

Now that we understand the importance of operational audits, let’s delve into the process of conducting one:

1. Planning:

The first step in any operational audit is careful planning. This involves defining the scope of the audit, setting objectives, and assembling a skilled audit team. The scope should encompass all relevant areas of the organization.

2. Data Collection:

With the audit plan in place, the next step is to gather data. This includes collecting information on processes, policies, and procedures. It’s essential to obtain both quantitative data (such as performance metrics) and qualitative data (like employee feedback).

3. Analysis:

Once the data is collected, it’s time for analysis. This phase involves evaluating the collected information against predetermined benchmarks or industry best practices. Analysts look for discrepancies, bottlenecks, and inefficiencies.

4. Corrective or Improvement Actions Planning:

Based on the findings, the audit team formulates recommendations for improvement. These recommendations should be actionable, specific, and prioritized according to their potential impact on efficiency.

5. Implementation:

Implementing the recommended changes is a critical phase. It requires collaboration between auditors and the organization’s management. Clear communication and a well-defined plan are essential for successful implementation.

6. Monitoring:

After changes are implemented, the audit process doesn’t end. Ongoing monitoring and follow-up audits are necessary to ensure that improvements are implemented in a time bound manner and that new issues are promptly addressed.

Operational Audit Frequency

The frequency of operational audits can vary significantly depending on the organization’s size, industry, and specific needs. However, it’s generally recommended that operational audits be conducted at least annually to ensure ongoing efficiency and compliance. In some cases, organizations in highly regulated industries or those experiencing rapid changes may benefit from more frequent audits, such as semi-annually or even quarterly. The key is to strike a balance between maintaining a vigilant eye on operations and allowing enough time for meaningful changes to be implemented between audits. Ultimately, the frequency should align with the organization’s strategic goals and the pace of change in its operational environment.

Operational Audit in Action

To illustrate the power of operational audits, let’s consider a real-life scenario. Imagine a manufacturing company that’s been experiencing declining profits. Despite high sales, costs have been soaring. An operational audit reveals several inefficiencies:

Production Line Delays: Excessive downtime due to equipment breakdowns and maintenance delays.

Inventory Management: Poorly managed inventory, resulting in overstocking of some items and shortages of others.

Supply Chain Issues: Inefficient procurement processes leading to higher material costs.

Quality Control Problems: Frequent product defects requiring costly rework.

Following the audit, the company takes action:

Production Line Improvements: Investing in maintenance and upgrading equipment to reduce downtime.

Inventory Optimization: Implementing a just-in-time inventory system to reduce carrying costs.

Streamlined Procurement: Negotiating better supplier contracts and adopting a more efficient procurement software.

Quality Control Measures: Implementing stricter quality control protocols to reduce defects.

Over the next year, the company sees significant improvements in its efficiency and profitability. Operational audits not only helped identify areas of concern but also provided practical solutions that led to tangible results.

Conclusion: It’s Time to Challenge the Status Quo

In the quest for efficiency and profitability, organizations must challenge their existing mindsets. Operational audits are not mere tools for cost-cutting; they are instruments of transformation. They challenge the way we perceive processes, resources, and opportunities within our organizations.

The message is clear: embrace operational audits, challenge the status quo, and unlock the true potential of your organization. It’s not just about saving costs; it’s about thriving in a competitive landscape where adaptability and efficiency are the keys to success. So, are you ready to challenge your organization’s mindset and unleash its untapped efficiency? The power of operational audits awaits your command.