section-00f3be2

Importance of Picking Process

Picking is a process of retrieving goods from their storage locations to fulfill customer orders. This is one process in the warehouse that has significant impact on the warehouse performance, namely, warehouse productivity and customer service.

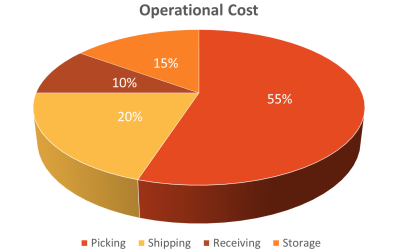

The typical operational cost break-up of warehouse cost shows more than 50% cost is spent on the picking process. Even today in most of the warehouses, picking process is manual and dependent on the skills and experience of the operators. The picking cost has been increasing due to SKU proliferation, smaller order quantity by the customers, especially with the growth of eCommerce channel.

Apart from the cost picking is also responsible for the errors in wrong products shipped, inventory inaccuracy, product damages, shipment delays etc. that may have serious implications for customer service.

Pain Points of Picking Process

1. Optimize the Warehouse Layout & Slotting

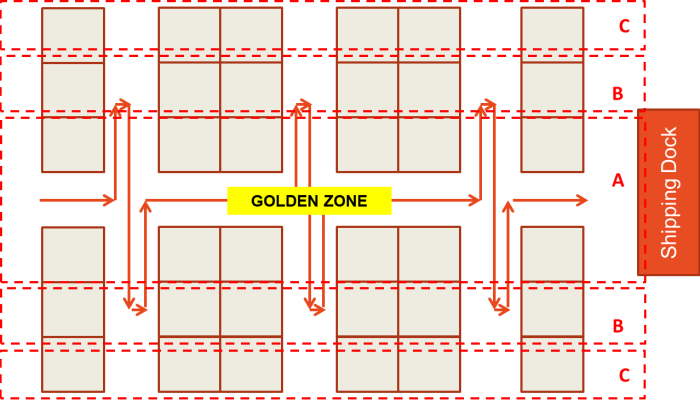

Warehouse layout and slotting of product have significant impact on the picking efficiency & accuracy. If the layout is optimized so that most frequently ordered products are slotted closer to the docks, the travel time of the pickers is minimized. The pickers can pick more orders in the same time leading to significant improvement in the productivity.

Also, if the inventory is organized according to the SKU codes & batches, the chances of errors by the pickers are minimized. It also reduces the search time of the picker thereby improving the productivity.

However, the business dynamics may change so rapidly that can make the layouts & picking process sub-optimized. Most warehouse managers are so occupied with day to day operations that they may not spend enough time to review the layout periodically.

2. Apply Right Picking Strategy

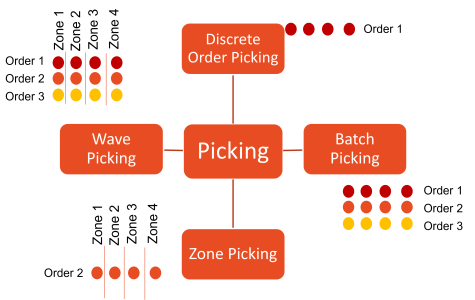

Picking strategies can vary depending on the customer orders profile and the warehouse layout. There are 4 picking strategies: Discrete, Batch, Zone and Wave picking.

The right picking strategy optimizes the time taken to pick each order and the travel time of the picker. Inappropriate picking strategy may lead to fewer orders picked by each operator, leading to lower productivity and delays in shipments.

3. Use Appropriate Technology & Automation

The objective of using technology for the picking process is to reduce picking time and improve picking accuracy. The appropriate technology depends on the the volume and complexity of the picking activity.

Barcode scanning along with Warehouse Management System is the one of the most commonly used technology. The other technologies are pick to light system, sorters & conveyors, robots etc. Each technology has its pros and cons, therefore, it is important to select the right combination of technologies that addresses the picking complexity for a warehouse.

4. Plan & Schedule Order Picking

Planning plays a very important role in the picking process to ensure optimal utilization of resources. In most cases, picking is triggered as & when new picklists are generated. It leads to under occupation of resources during certain times and over occupation in the other times.

By planning the picking activity in advance based on the planned shipments would help in levelling the resource requirement leading to minimal idling as well as overtime. Some of the planning techniques that can achieve this objective are:

- Combining high resource intensive picks with low resource intensive picks

- Sequencing the picks based on the shipment loads

- Prioritization of picks based on the order priority - orders with lower priorities can be picked next day

- Creating picking teams based on zones or docks and ensuring coordination with the staging and shipping teams

5. Use Visual Management Techniques

Whatever is visual and eye catching, gets more attention of the human beings. Since the picking activity has a huge involvement of people, visual management is very effective in ensuring discipline and adherence to the process.

Some of the ideas for Visual Management for picking are:

- Display location codes / numbers of the storage location prominently. It will minimize the search time of the pickers & improve productivity.

- Segregate and place signboards on the products that are not supposed to be picked e.g. quality hold, expired, damaged or red tag zone. It will minimize the errors & improve the accuracy.

- Use LED Boards to display the picking target for the day, picks completed and picks balance. It is a great motivator for completing the target for the picking operation.

6. Periodically Audit Picking Process

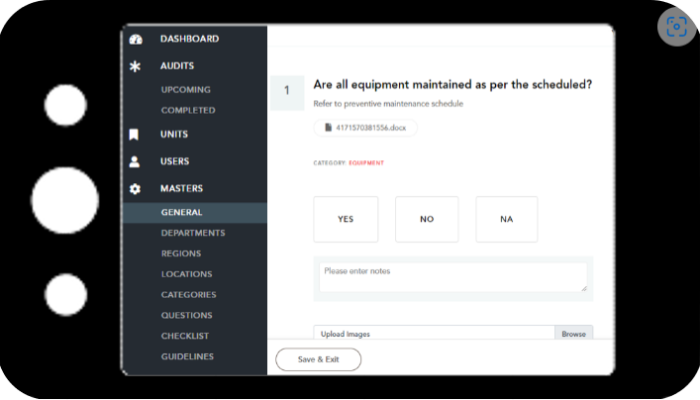

Warehouses are under constant pressure for timely delivery of products. As a result, many shortcuts are taken and exceptions become the rule. If such deviations and bad practices are not identified and addressed timely, it may lead to major incidents or failures.

Periodic warehouse audits ensures that gaps & risks in the operations are addressed in a structured manner. SIMSA Audit and Improvement tool enables digitization of audit schedules, reporting as well as tracking corrective actions leading to operational improvements. SIMSA can save up to 70% of the time in managing the warehouse audits as compared to using spreadsheets. Also, it provides full visibility to all stakeholders on various gaps and actions taken.

Download the free editable Warehouse Picking Process checklist here.

7. Measure, Monitor and Improve Picking Performance

What you don't measure, you cannot Control. And what you don't Control, you cannot Improve.

It goes without saying that measurement of the performance picking process helps to understand its impact on overall efficiency & cost. It may also point to certain changes that may be required either in the warehouse layout, reorganization of SKUs, resource allocation, automation or even training the operators.

The common performance indicators for the picking process are:

- Pick to Ship Time

- Backorder Rate

- Picking accuracy (Perfect Order Fulfillment)

- Units picked per resource (Productivity)

Analyzing the performance indicators, performing the root cause analysis and following PDCA cycle enables continuous improvement in the picking process.